| Home | Group Members | Research Areas | Research Facilities | Research Collaborations | Classes | Publications | News & Awards | Directions to NCEL |

Contact Info:

Mark J. Rood, Ph.D.

Ivan Racheff Professor of Environmental Engineering

Department of Civil and Environmental Engineering

University of Illinois

3230E Newmark Lab, MC-250

205 N. Mathews Ave.

Urbana, IL 61801 USA

Tel. (217) 333-6963

Fax. (217) 333-9464

mrood@illinois.edu

Development of Novel Carbon-Based Catalysts and Adsorbents

Research Currently being performed by:

|

|

|

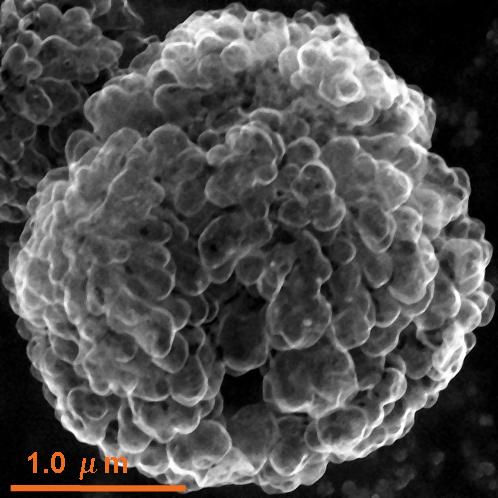

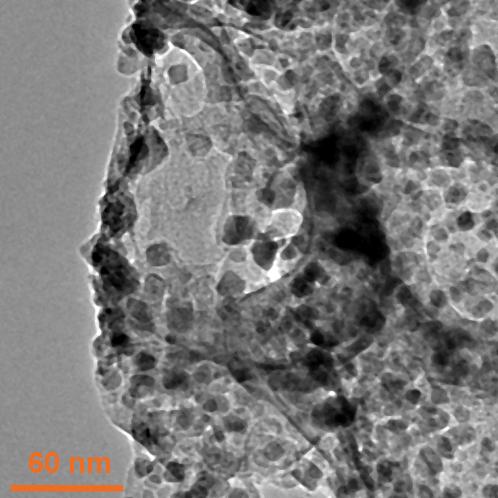

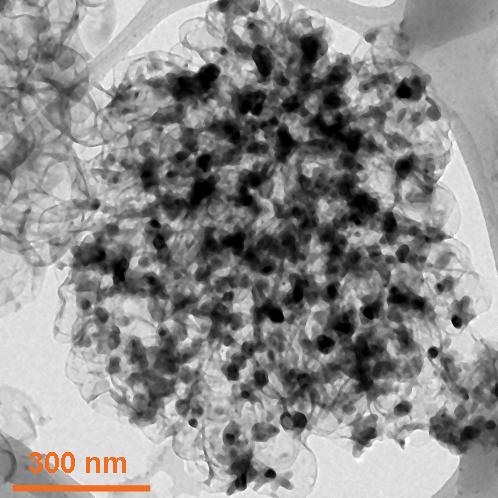

Figure 1 - SEM and TEM Images of Iron-Impregnated Carbon Supported

Catalysts (FeCSCs) prepared in a single step using Ultrasonic Spray Pyrolysis

Traditional methods for porous carbon production involve two steps: pyrolysis to carbonize an organic precursor followed by activation (either physical or chemical) of the carbon-based product. Extensive literature exists describing these well-established techniques using organic precursors such as coal and biomass. At the University of Illinois (with collaboration from the Illinois State Geological Survey), we are using new production techniques to produce unique carbon materials for environmental applications. First, a simple process for producing porous carbon from solid organic salt precursors was developed to prepare a new class of carbon material (Figure 2). The precursor is pyrolyzed at 400 - 1200 o C in a fixed-bed reactor. During thermal decomposition, leaving groups are expelled from the precursor, allowing for carbon isolation. The isolated carbon networks around the precursor's inorganic component, allowing for simultaneous carbonization and pore formation. Dissolving the inorganic salt matrix in water isolates the porous carbon product. |

Figure 2 - Two-Step Process for production of porous carbons from organic

salt precursors

With Ultrasonic Spray Pyrolysis (USP), a similar process is being used to produce catalyst-impregnated carbons in a single step (Figure 3). By mixing the carbon and catalyst precursors, dissolving the mixture in water, and aerosolizing the solution before thermal treatment, we can produce porous carbon supports impregnated with nano-scale catalysts - all in a single step . This process greatly simplifies the traditional 4-step (carbonization, activation, catalyst impregnation, catalyst activation) process used for preparing carbon supported catalysts. Characterization results show that carbon microspheres impregnated with well dispersed, iron nano-particles can be prepared (Figure 1). Adsorptive and catalytic properties of these novel carbon materials are currently being evaluated. |

Figure 3 - Ultrasonic Spray Pyrolysis (USP) apparatus used for producing FeCSCs

(modified from Skrabalak and Suslick, 2006)